Techniques

As with any artisan. there are many skills that are developed and honed through countless hours of practice. Mastery in each skill is required to bring about a fine leather good. All of our techniques are based on traditional methods developed over the centuries and rely entirely on hand tools.

While no means exhaustive, below is a sampling of the various skills that we employ and continue to improve every day.

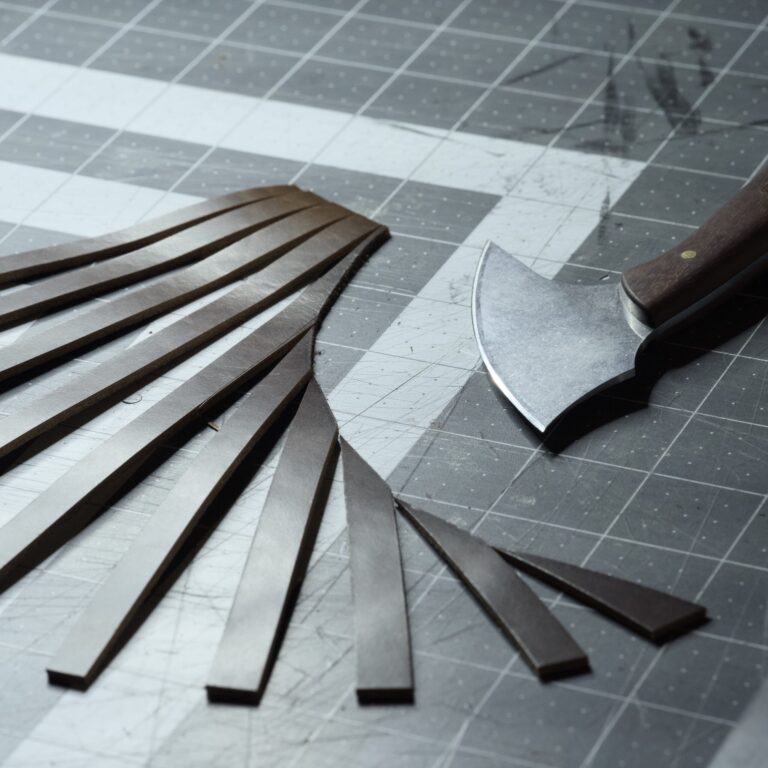

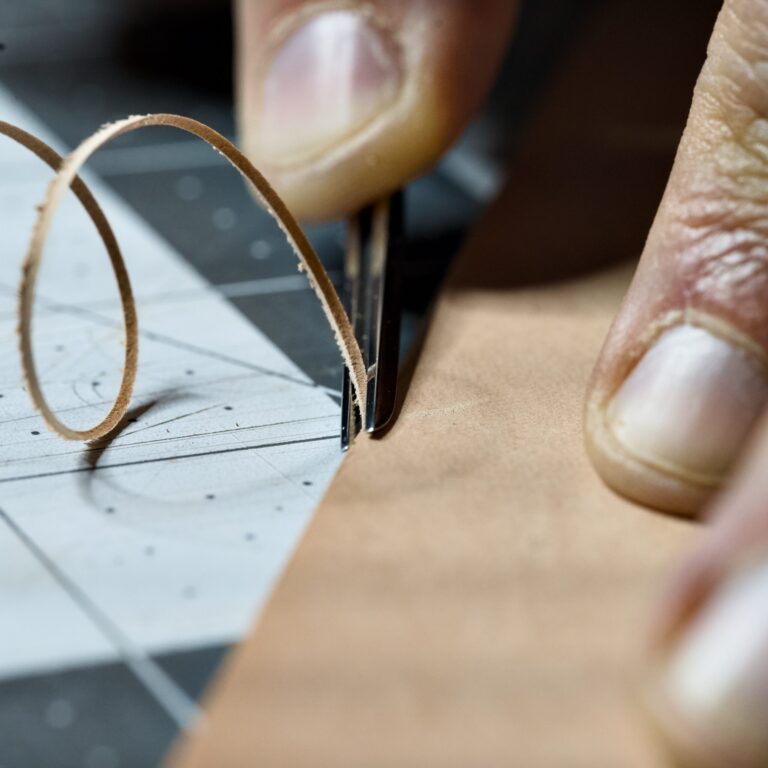

Cutting: Prior to anything being assembled, the leather has to be measured, marked and cut with razor sharp knives and punches to create the straight lines, curves and holes within the leather. Unlike wood, some leathers stretch while cutting, adding complexity to achieving a straight even cut.

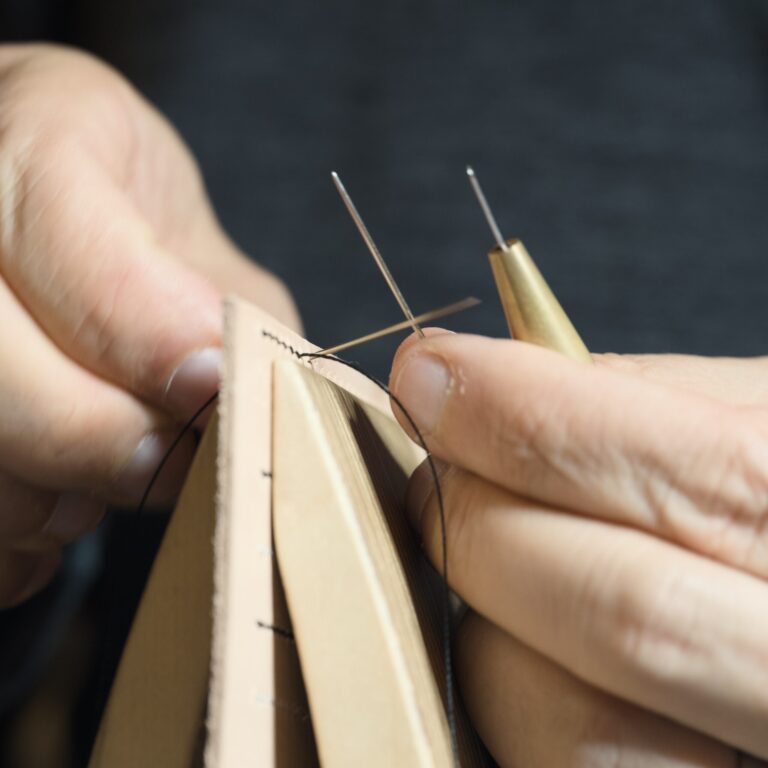

Stitching: The saddle stitch, is just one example of a stitch and can only be completed by hand. This requires interweaving the thread from each side through every hole, creating a stronger stitch than available from a machine. To make the holes, a pricking iron is used to mark the leather and an awl pushes through allowing the needles and thread to pass.

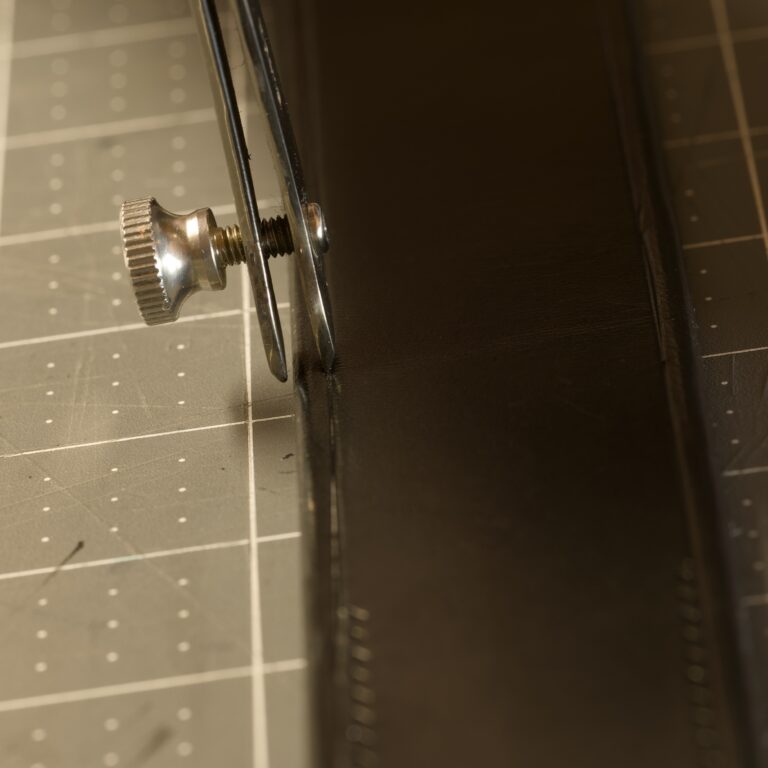

Skiving: This process thins down the edges of the leather, reducing the overall bulk of the leather good. It is imperative that the the thinning is completed in a consistent manner along either edge. In some cases, skiving is completed to produce a feather edge, making seams near impossible to see.

Creasing: Adds a decorative line to the product, many times helping to set off the stitching. It also has a practical purpose. By heating and compressing the leather close to the edge, it reduce the amount of moisture that is pulled into the body of the leather from the edge, increasing longevity and durability.

Bevelling: This process is used to shape the edge of a leather good. By rounding off the edges, the item is softer in the hand without harsh edges. There is also a practical benefit, as a rounded edge will hold up better to daily use than a squared edge and is less likely to be damaged or caught on something else.

Edge painting: Is another form of protecting the edges of leather good. It provides a barrier to moisture, while adding a decorative element to the leather. The edge paint used adheres to the leather and maintains flexibility over time. A minimum of three coats of edge paint are applied, and sanded smooth in between each application.

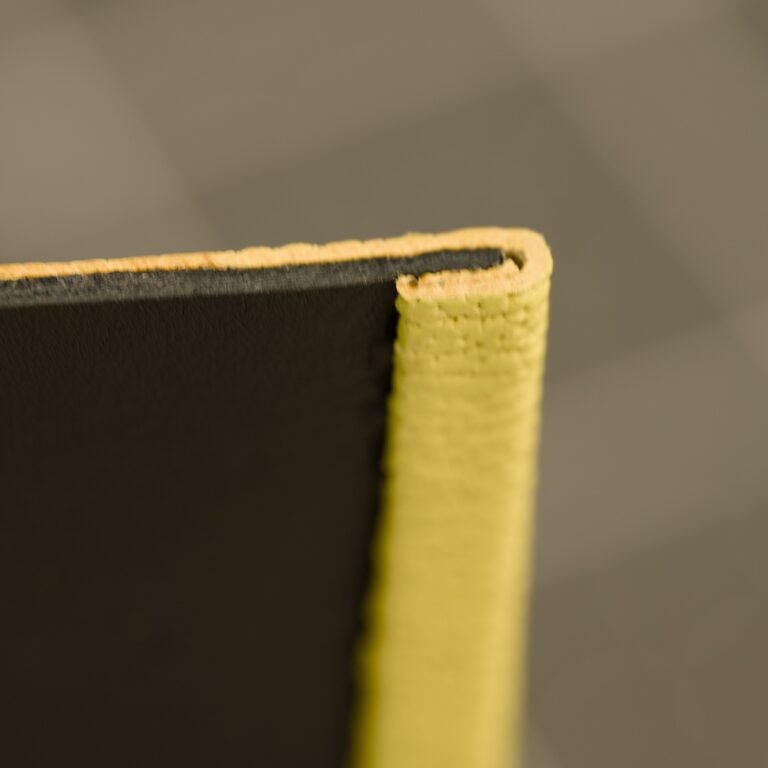

Turned edges: Requiring higher skill, and increasing overall durability of the good is a turned edge. This uses the leather itself to finish the edge rather than paint or burnishing. There are many different styles of turned edge, but not every good allows for a turned edge. Where possible, different styles of turned edge have been incorporated into the goods we offer for sale.